June 6, 1944, Normandy Beach. A Sherman tank named Fury takes a direct hit; the crew abandons it. The mission is over—except one man refuses to leave. Sergeant Curtis Cullen had no engineering degree, no special training—just a wild idea involving scrap metal and a welding torch. His commanding officer called him insane. What he built in 48 hours would change the invasion: one broken tank, one “mad” mechanic, and a design so simple and brilliant that Eisenhower ordered 5,000 copies. This is the story they don’t teach in history class—the tale of how a sergeant with a blowtorch saved D-Day. Stay until the end; what happened next shocked everyone.

Normandy, France—June 1944—six days after D-Day, the Allied advance had ground to a halt. Not because of German tanks or artillery, but because of hedgerows. These weren’t decorative shrubs; Norman hedgerows were ancient walls of earth, stone, and tangled roots—built over centuries to mark boundaries. Some stood fifteen feet tall and just as thick; roots plunged ten feet deep. Natural fortresses covered Normandy like a maze.

For American tank crews, hedgerows became death traps. Each time a Sherman tried to climb over, its thin belly armor—the vehicle’s most vulnerable area—was exposed. German soldiers positioned on the far side with anti-tank weapons simply waited. The instant a Sherman’s underside appeared, they fired—one shot, one kill. Over and over, Sergeant Curtis Cullen of the 102nd Cavalry Reconnaissance Squadron watched the nightmare unfold.

He saw tanks approach a hedgerow, tilt upward, and then erupt in flames. Crews rarely survived; those who did were traumatized, burned, or both. Medics were overwhelmed; morgue details worked overtime. The tactical situation was desperate. Allied planners expected to be thirty miles inland, pushing toward Paris; instead, they were stuck in a dense network of hedgerows—advancing a few hundred yards a day. Every field became a separate battle; every hedgerow, a new problem.

The Germans didn’t need massive reinforcements; they just waited behind natural barriers and picked off American armor as it exposed itself. Cullen wasn’t an engineer; he had no college. Before the war, he was a New Jersey mechanic—fixing cars and trucks—but he understood machines. He understood leverage and force. Watching another Sherman burn as it tried to climb a hedge, something clicked.

The problem wasn’t the hedgerows; it was that tanks were going over instead of through. If you could cut at ground level—plow through rather than climb—the belly armor would never be exposed. Germans can’t shoot what they can’t see. But how do you cut through ten feet of compacted earth, stone, and roots—fortified by centuries of weather? They wouldn’t yield to anything but massive force applied precisely.

Cullen began sketching in his pocket notebook. Crewmates joked he was trying to solve the whole war with little drawings. Affection mixed with skepticism—smart people had studied the hedge problem; none solved it. Why would a sergeant do better? Cullen ignored them. Mechanics were underestimated; people assumed hands meant no mind. Every good mechanic is a problem solver—every repair a puzzle. You learn how forces interact and how to make stubborn machinery behave. Hedgerows were stubborn machinery—persuasion required. Cullen thought he knew how—he needed a broken tank, scrap metal, and an officer crazy enough to authorize the attempt.

He approached Captain Samuel Morrison with a proposal that sounded insane. Take a damaged but mobile Sherman and weld steel prongs to its front—made from German anti-tank obstacles called Czech hedgehogs scattered on the beaches. The prongs would act like giant knives: the tank would ram the hedgerow at speed; the prongs would dig and rip earth and roots, creating a path. Morrison stared like Cullen had lost his mind.

“Let me understand—take a tank already shot at, weld scrap to it, then drive full speed into an earthen wall. That’s your plan?” “Yes, sir,” Cullen said calmly. “Right now we drive over hedgerows and expose the belly. My plan keeps frontal armor toward the enemy—Germans need a belly shot. If we never give it, they can’t kill the tank.” The logic was sound—still crazy. Welding modifications in a combat zone—using untested equipment. If it failed, good tanks and crews would be lost. If it worked, they might finally make progress.

“How long to build?” Morrison asked. “Two days. Welding gear and permission to scavenge beach obstacles. I’ll have a prototype.” Morrison made a decision that changed the campaign: “You have 48 hours. If this doesn’t work, we’ll be explaining ourselves to angry generals.” Cullen saluted and went to work immediately.

He requisitioned an acetylene torch, welding equipment, and a work crew—then headed to the D-Day beaches. German defensive obstacles littered the sand—meant to stop landing craft—now scrap waiting for repurposing. Czech hedgehogs were perfect—three heavy iron beams welded in a giant jack—hardened steel weighing hundreds of pounds. Thousands dotted the beaches.

Cullen’s crew cut hedgehogs apart with torches—working through the night—trimming beams to roughly four feet—sharpening tips—reinforcing welds. By day’s end, four prongs were ready—each thick as a man’s leg and hard as railroad track. The next phase was delicate: weld prongs to a Sherman’s front without compromising structure or movement. Cullen calculated angles carefully—low enough to bite the base, spaced to rip a broad section, strong enough to withstand impact without snapping.

“You really think this will work?” Private Eddie Kowalski asked, watching Cullen adjust his mask. “I know it will,” Cullen replied. “Physics are solid—steel teeth driven by thirty tons into earth and roots. Something gives—and it won’t be the steel.” By dawn of day two, the modification was complete. The Sherman now had four steel prongs extending like tusks from a mechanical beast.

Soldiers gathered to stare. Some impressed—others skeptical—bets placed on whether Cullen would be court-martialed or commended. “Looks like a pig trying to mate with a porcupine,” one joked. Cullen patted a prong. “Maybe so—but this pig’s going to root through every hedgerow between here and Berlin.” Captain Morrison circled the tank—examined welds—tested strength—then nodded. “All right, Sergeant. You’ve built your mad contraption. Prove it works. Tomorrow morning we’ll find a thick hedgerow and see if this is genius or suicide.”

That night, Cullen couldn’t sleep—running calculations again and again. The math worked; the engineering was sound—but theory isn’t reality. What if prongs snapped? What if they dug too deep and stuck? What if the contraption made things worse? He thought of burning Shermans and crews who never made it out—hedgerows turning Normandy into a graveyard for American armor. Something had to change—and if his idea worked, it could save hundreds of lives. Tomorrow would tell.

At dawn, the modified Sherman rolled toward a particularly thick hedge chosen for the test—twelve feet high—ancient—impenetrable. Officers gathered—Morrison among them—with Major Jack Williams from division HQ. The crew volunteered: driver Corporal Jake Mitchell, gunner Sergeant Tom Harrison, loader PFC Danny Chen—brave or crazy—maybe both. Hatches buttoned—engine rumbling—soldiers fell silent.

Cullen stood with observers—heart pounding—everything he’d built came down to sixty seconds. If it worked, they’d revolutionize the campaign. If it failed catastrophically, men might die—and he’d bear that weight. “Ready?” Morrison asked. “As I’ll ever be, sir.” Morrison dropped his arm—signal to proceed. The Sherman’s engine roared—black smoke belched—then, gathering speed, it charged the hedge—thirty tons of steel against an immovable object.

The impact thundered—the tank shuddered—earth exploded outward—roots snapped like rifle shots. For a moment the tank stalled—embedded in mass—soldiers held breath. Slowly, the Sherman began to move forward. The steel prongs dug deep—creating leverage—ripping roots and stone. The tank tilted slightly nose-down—never exposing its belly—frontal armor facing any threat. More roots snapped—dirt cascaded—engine screamed—and suddenly the Sherman burst through—emerging into the field beyond.

A perfect breach—wide enough for vehicles to follow—low enough that the vulnerable underside never showed. Soldiers erupted in cheers—Cullen’s knees went weak with relief. It had worked. The crew popped hatches—grinning. “Smoothest hedgerow crossing I’ve ever felt,” Mitchell shouted. “We barely felt impact—and never exposed our belly.” Major Williams approached Cullen—serious. “Sergeant, how many can you produce—and how quickly?”

“Sir, with enough welders and more hedgehogs, my crew could modify ten tanks a day—maybe more if we push.” “Not good enough,” Williams said—and Cullen’s heart sank—then the major smiled. “I’ll get you fifty welders and all the steel you need. I want a hundred tanks by week’s end—and I’m sending a report to General Bradley. This invention will change everything.” Morrison clapped Cullen’s back. “Congratulations—you’re no longer the mad mechanic. You’re the genius who just saved the Normandy campaign.”

Cullen wasn’t celebrating yet. “Sir, one test isn’t combat. We need to try it against a real position under enemy fire.” Morrison nodded. “There’s a German strongpoint two miles from here—holding us for three days—every approach blocked by hedgerows. If your modification works there under fire, it’s proven.” “When do we go?” “Tomorrow at dawn. You’ll ride with Mitchell’s crew as technical advisor. If problems occur, you’ll see them.”

Cullen swallowed—he’d hoped to stay back and build more—but Morrison was right—combat was the only proof. “Understood, sir.” That night, Cullen checked every weld—tightened bolts—examined prongs for stress—everything looked solid—but battle is never controlled. Private Chen found him working by lantern light. “Sergeant, you should rest. Big day tomorrow.” “Can’t sleep—too much thinking.” “You scared?”

“Terrified,” Cullen said. “It works in theory and one test—but tomorrow lives depend on whether I got the math right. If I missed anything—if there’s a flaw—” “We trust you saw everything,” Chen said simply. “You built it. You know it best. Tomorrow, we’ll plow through those hedgerows and show the Germans they can’t hide.”

Dawn broke cold and drizzling—Cullen climbed into the commander’s cupola—nerves churning. The plan was straightforward: their tank, nicknamed Rhinoceros, would lead a small column toward the strongpoint—using the cutter to breach previously impassable barriers—infantry close behind to exploit the breaches and avoid killing zones. “Mount up.” Engines rumbled across the staging area—Rhinoceros rolled—steel prongs gleaming in gray light.

They approached the first hedgerow—beyond it a machine gun nest mowing down Americans for days. The usual tactic would climb and expose the belly to a Panzerfaust—punching through weak armor like paper. “Steady,” Cullen said over intercom. “Hit at a slight angle—twenty degrees—to help the prongs bite.” “Roger,” Mitchell replied—adjusting.

The crash was bone-jarring—earth and roots exploded—crew slammed against restraints—but nothing broke. Prongs held—tank pushed—engine screaming—tracks churning—ripping centuries-old growth—and then they were through—emerging to find a shocked German crew scrambling. The main gun spoke—one HE round—threat eliminated. “It works,” Chen shouted. “It works in combat.”

No time to celebrate—more hedgerows ahead—enemy behind each. Rhinoceros continued—breaching after breaching—prongs performing—every emergence beating anti-tank weapons to the draw. Infantry poured through breaches—clearing positions that had seemed impregnable hours earlier.

Then came the real test: a German Panther—far more dangerous—positioned behind a massive hedgerow. Its 75mm gun could destroy a Sherman at range. If Rhinoceros got stuck breaching, it would be a sitting duck. “Contact front,” Harrison called. “Panther—partial cover.” Cullen’s mind raced: retreat and call artillery—or change the rules.

“Breach the hedge,” he ordered. “Don’t stop—go through fast—emerge with gun already aimed on the Panther. Speed is our advantage.” Mitchell didn’t hesitate—the Sherman surged. The impact was massive—thicker than anything yet—terrifyingly, the tank seemed to slow—prongs struggling. “More power,” Cullen shouted. “Give it everything.”

The engine howled—smoke poured—tracks threw up clouds of earth—and inch by inch, Rhinoceros forced through—bursting out at an angle—imperfect but enough. Harrison had kept his gun trained; as they emerged, the Panther’s turret was still turning—he fired first. The AP round struck side armor—thinner than the front—and penetrated. Smoke poured—crew bailed—Rhinoceros’s machine guns convinced them to surrender. Infantry secured prisoners.

An officer approached—grinning. “Sergeant Cullen, I don’t know what witchcraft you worked—but you did in two hours what we’d tried for three days. That strongpoint is finished.” Cullen climbed out—legs shaky. The design had worked—not just in test—but under fire. His “mad” idea had proven itself.

Morrison arrived—radio crackling with reports. “Sergeant, division just called—General Bradley wants to see you. Major Williams’s report impressed. They’re calling it the Cullen hedgerow cutter—and want 5,000 immediately.” Five thousand. Cullen could barely process it. A 48-hour scrap-metal modification would be mass-produced across the Allied armored force.

“Sir, I’m just a mechanic—” “You’re the man who solved the hedge problem,” Morrison cut in. “Own it—you changed the war.” Within days of Rhinoceros’s success, every tank depot in Normandy received orders to install cutters. The Army brought in welding teams—scavenged more hedgehogs—set up field assembly lines—working around the clock.

Cullen was pulled to train crews—moving depot to depot—teaching prong angles, welding techniques, reinforcement methods to prevent snap-offs under stress. “Key is prongs dig low,” he told welders. “Too high and the tank tilts—exposes belly. Too low and you plow dirt without cutting roots. Position exactly here”—chalk mark at a fifteen-degree downward angle—“for optimal cutting.”

Skeptical welders changed their minds after combat footage showed Rhinoceroses plowing hedgerows that had stopped everything else. They worked faster—proud of the modifications. General Omar Bradley visited a site—found Cullen elbow-deep in a training weld. “Sergeant Cullen, I presume.” Cullen snapped to attention. “At ease,” Bradley smiled. “I came to see the man who unstuck my army.”

“Your invention is brilliant in its simplicity. We tried sophisticated solutions—artillery, explosives, dozers—none worked consistently. You used scrap and a torch and solved it in two days.” “Sir, I just—” “—did what needed doing,” Bradley finished. “I’m recommending the Legion of Merit and authorizing a field promotion to Technical Sergeant. This army needs men who think outside the box.”

After Bradley left, crewmates mobbed Cullen—congratulations—while he felt conflicted. He was lauded as a genius, receiving medals and promotions—but men were still dying. The cutter helped—but wasn’t magic—the war continued. Private Kowalski, who’d helped build the prototype, pulled him aside. “You okay, Sarge?”

“I keep thinking of crews we lost before the invention. What if I’d thought sooner? Pushed harder?” “You can’t think like that,” Kowalski said firmly. “You can’t save those already gone. You’re saving those alive now. Every day more tanks with your cutters roll through hedgerows—every day fewer crews burn. That’s what matters.”

Cullen embraced field feedback. The cutter worked brilliantly—but could improve. Some crews added a fifth central prong for thick hedgerows. Others serrated edges to grip stubborn roots. A few added reinforcement plates to protect welds from small arms fire. “I never claimed it was perfect—just that it worked,” Cullen told a correspondent. “If soldiers can make it better, I want to learn.”

A clever tweak came from a Third Armored crew—cutters clogged with packed earth and roots—reducing effectiveness on successive hedgerows. They added a simple mechanism inspired by agricultural harrows—clearing debris as the tank moved. Small change—big impact—breaching multiple hedgerows without stopping. Cullen immediately incorporated it into training. “That’s genius,” he told crews. “I never thought about debris clearance. A tanker saw the problem and fixed it. That’s how good engineering happens—iterative—input from users.”

German response was initially baffled—after-action reports noted enemy armor passing through hedgerows without exposing vulnerable areas—unknown how. Once they understood, they tried counters: mines embedded in hedgerows—anti-tank guns positioned to catch breaching tanks—fake hedgerows as traps. None worked consistently. The fundamental advantage remained: cutters allowed breaching while keeping frontal armor toward the enemy. With proper tactics, Germans couldn’t effectively counter.

By August 1944, as Allies broke out of Normandy and raced across France, cutters became standard. New Shermans rolling off U.S. lines were built with attachment points welded in. The field modification became official design. Cullen had changed how tanks were built.

As forces moved into open terrain, original use declined—but crews discovered new applications. In urban warfare, prongs smashed brick walls and wooden barricades—breaching buildings with snipers—devastating psychological effect—thirty tons crashing through a wall convinced defenders to surrender. In river crossings, prongs added traction on muddy banks—preventing slides. In winter, cutters pushed through snowdrifts—acting like plows—clearing paths for troops and vehicles.

Cullen—now a Master Sergeant attached to an engineering evaluation team—traveled to units—studied creative uses—took notes—sketched modifications—recommended improvements. “I never imagined all this,” he wrote home. “I just wanted to get through hedgerows—but soldiers are creative. They’ll use any tool for whatever purpose. My cutters became multipurpose battlefield tools.”

The most unexpected use came during the Battle of the Bulge. Germans felled trees to block roads—crews used cutters to break or push obstacles—keeping columns moving. One report described using a cutter to shove a disabled German tank out of a narrow road—hooking prongs under skirt armor and pushing aside—preventing hours of delay. Cullen smiled. “I built a tool to cut bushes—and now they’re moving panzers. War makes you creative.”

Not all news was positive. Some tanks suffered failures when cutters were used beyond design—prongs snapped on reinforced concrete—welds failed lifting heavy objects—friendly fire incidents when units didn’t recognize modified silhouettes in poor visibility. Cullen worked with engineers to improve training. “The cutter is a tool—not magic,” he emphasized. “It has limits. Use it wrong and you break it—or get someone killed. Use it right and it saves your life.”

By early 1945, as Allies pushed into Germany, cutters were so standard that new tankers barely remembered Shermans without them. The innovation had normalized—integrated into doctrine. For Cullen, it was gratifying and melancholy. Success meant people forgot the problem had ever existed. “That’s how you know something really worked,” Morrison told him. “When people can’t imagine it being different. You didn’t just solve a problem—you erased it.”

There were costs and consequences Cullen hadn’t anticipated. Human cost: with tanks breaching hedgerows, commanders used armor more aggressively—launching attacks that might have been delayed—some units took casualties that caution might have avoided. Cullen wrestled with guilt. “Did I give commanders a tool that made them overconfident?” he asked Chaplain Thomas O’Brien. “You gave a tool that saved lives,” O’Brien replied. “What commanders do with it—that’s on them. You can’t control how people use what you create—only aim for more good than harm.”

Another cost: German defenders. Cutters shortened the campaign—saving Allied lives—but also meant German soldiers who might have survived a longer advance died in the rapid push the cutters enabled. Intellectually, that’s war—defeat the enemy. Emotionally, harder to process. “I killed people I never saw,” he confessed to Kowalski. “Not directly—but my invention put tanks where they killed more efficiently. I’m decorated for making killing more efficient.” Kowalski answered softly: “You stopped good men from burning in tanks. Yes, it killed Germans—it’s a weapon modification—that’s its purpose. It also saved Americans—and shortened the war—saving lives on all sides. Even if it doesn’t feel like it.”

There were practical costs—logistics stress. Rapid advances enabled by cutters meant supply struggled to keep up—fuel, ammo, parts rushed to units miles ahead of plan—some ran out and halted—creating vulnerabilities. Cullen met with logistics officers—explaining that success created problems needing solutions. “I gave you a tool making tanks more effective,” he said. “You need to keep them supplied when they advance faster than planned.” It was odd—an enlisted sergeant advising strategy—but his perspective mattered. The Army adapted—new logistics procedures—supply methods—matching faster tempo.

Perhaps strangest was psychological cost—Cullen became famous—the genius mechanic who solved the impossible. Soldiers asked autographs; officers wanted him at briefings; correspondents sought interviews. He hated it. “I’m just a guy who had an idea,” he told Morrison. “I didn’t storm beaches or charge machine guns. I welded metal to a tank. Why am I treated like a hero when real heroes die?”

“You’re modest—that’s admirable,” Morrison said. “But understand: soldiers charging nests are heroes for courage. You’re a hero for your mind. Both are necessary. Accept it—you’ve earned it.” Cullen reluctantly accepted recognition—never comfortable. In his mind, he remained a New Jersey mechanic who figured out how to cut through bushes.

Germany surrendered May 8, 1945. The war in Europe ended. Cullen stood with his unit in a small German town—watching celebrations—joy, relief, exhaustion—emotions too complex to name. The cutters had played their part. By most estimates, they shortened Normandy by weeks—possibly months—cascading into faster advances across France, quicker liberation of Paris, earlier Rhine crossing, sooner Berlin. Every day saved meant lives saved, resources conserved, suffering reduced.

Official citations credited the Cullen Hedgerow Cutter with materially contributing to the successful conclusion of the Normandy campaign and subsequent European operations. Eisenhower called it among the war’s most significant tactical innovations. Cullen received the Legion of Merit, the Bronze Star, and a commendation from the Supreme Allied Commander—promoted to Warrant Officer—name in newspapers—symbol of American ingenuity: an average soldier using common sense and scrap to solve a problem that stumped experts.

Standing in that town, Cullen felt empty. The problem he solved no longer mattered; the war was over; Normandy’s hedgerows were a year behind. His invention—revolutionary—was now a footnote in a war that killed tens of millions. “You’re thinking too much again,” Kowalski said—handing him two liberated beers. “Just reflecting,” Cullen replied. “A year ago I welded prongs—hoping it would work. Now the war’s over—and I’m wondering what any of it meant.”

“It meant you saved lives,” Kowalski said. “Mine, probably. If tanks hadn’t breached hedgerows, I’d likely be dead—and hundreds of others. Your invention mattered. Don’t doubt it.” They drank in silence—sunset over a ruined Germany. Cullen thought about choices—if he’d dismissed the idea as too simple—if Morrison had refused—if the test failed—if combat trial went wrong—any moment could have changed everything.

“You know what’s strange?” Cullen said. “I keep thinking about German tankers—sitting behind hedgerows—confident—then American tanks burst through barriers supposed to be impenetrable. How did it feel when the rules of warfare changed overnight?” “Like losing,” Kowalski said. “Which is what they deserved for starting this mess.” Cullen nodded—unable to shake the thought. War was full of innovations—each side seeking edges—changing rules. His cutter was one example—radar, proximity fuses, armor, tactics—countless others—each making someone’s defenses obsolete—preparations worthless. That’s the nature of war—and progress. Solve a problem in war and you prove problems can be solved.

“I wonder what happens to all those cutters now,” Cullen mused. “Thousands of tanks with prongs welded on. What do you do when there are no more hedgerows?” “Scrap them,” Kowalski said. “Or leave them on as souvenirs. Either way—they did their job. That’s all any tool can ask.”

Curtis Cullen returned to New Jersey in late 1945—decorations and memories—ready to leave war behind. He went back to his old job—fixing cars and trucks—skills of wartime innovation serving in peacetime—good with machines—solving problems—seeing solutions others missed. He rarely talked about the cutter. When asked, he deflected: “I was a mechanic—fixed tanks—nothing exciting.” He didn’t mention medals, innovations, or changing Normandy’s course.

His wife, Margaret, once asked why he avoided wartime achievements. “You’re a genuine hero—be proud.” “I’m proud of what I did,” Cullen replied softly. “Not proud of what it was for. I made a tool that helped kill people. It saved American lives—that matters—but it was still about killing. I’d rather focus on fixing things now—not how I helped break things then.”

Over decades, historians recognized the cutter’s significance—appearing in Normandy histories, WWII innovation documentaries, and training manuals as field-expedient engineering. But Cullen remained largely unknown outside military circles. In 1984, forty years after D-Day, historian David Carter tracked down Cullen—now seventy-three and retired—writing a book on tactical innovation—seeking the cutter’s inventor.

“Mr. Cullen, do you understand how significant your invention was?” Carter asked. “Analysts estimate it shortened Normandy by weeks, saved thousands, changed doctrine. And it all came from you—a sergeant without an engineering degree—in forty-eight hours.” Cullen was silent—then offered a summary of American ingenuity that Carter later printed.

“I wasn’t special. I was just a guy who knew how machines worked and saw a problem that needed solving. The special part was the Army gave me a chance to try. How many good ideas got dismissed because they came from the wrong person? How many problems went unsolved because someone said ‘that’s not how we do things’? I got lucky. My crazy idea got tested. I guarantee there were a hundred other guys with equally good ideas nobody listened to.”

“But your idea worked,” Carter pressed. “That makes you special.” “My idea worked because people gave it a chance,” Cullen corrected. “Morrison could’ve said no. The test crew could’ve refused. Division could’ve rejected it after combat. They didn’t. They looked at the idea—not the person. That’s the real lesson: good ideas can come from anywhere—if you’re willing to listen.”

Curtis Cullen died in 1963. His obituary in the local paper mentioned he was a mechanic, a veteran, and a quiet man who preferred fixing to talking. It didn’t mention the hedgerow cutter. Most neighbors never knew the old man who fixed their cars had changed World War II. But in military museums across America and Europe, examples of the Cullen Hedgerow Cutter are preserved—chunks of steel welded to Sherman fronts—simple and crude-looking—but revolutionary in effect.

Plaques explain what they are and what they did—and sometimes mention the name Curtis Cullen—the “mad” mechanic who refused to accept unsolvable problems.

News

Emma Rowena Gatewood was sixty‑seven years old, weighed about 150 pounds, and wore a size 8 shoe the day she walked out of the ordinary world and into the wilderness.

On paper, she looked like anyone’s grandmother. In reality, she was about to change hiking history forever. It was 1955….

21 Years Old, Stuck in a Lonely Weather Station – and She Accidentally Saved Tens of Thousands of Allied Soldiers

Three days before D‑Day, a 21‑year‑old Irish woman walked down a damp, wind‑bitten corridor and did something she’d already done…

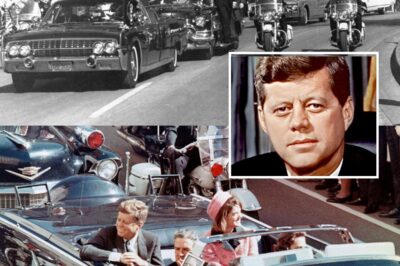

JFK’s Assassination Was Way Worse Than You Thought

So, he’s finally done it. What do these new documents tell us about that fateful day in Dallas? In 2025,…

US Navy USS Saufley DD465 1952 Living Conditions

The USS Southerly was a general‑purpose 2,100‑ton destroyer of the Fletcher class. She was originally equipped to provide anti‑aircraft, surface,…

Man Finds Birth Mother and Uncovers His Family’s Unbelievable Past

Air Force Colonel Bruce Hollywood always knew he’d been adopted. His Asian features clearly didn’t come from his parents, who…

Before the wedding began the bride overheard the groom’s confession and her revenge stunned everyone

The bride heard the groom’s confession minutes before the wedding. Her revenge surprised everyone. Valentina Miller felt her legs trembling…

End of content

No more pages to load