Picture this. It is 1944. You are deep in the steaming, suffocating jungles of Burma. The air is so thick with humidity you can practically drink it.

Suddenly, you hear a sound tearing through the canopy. It’s the rhythmic metallic *clack clack clack* of a train rolling down the tracks. You hear the high‑pitched toot of a whistle.

You look through the fern leaves, expecting to see a massive steam locomotive bellowing black smoke, maybe hauling howitzers or crates of ammunition. But when the machine bursts into the clearing, your brain takes a second to process what you are seeing.

It isn’t a train. It isn’t a locomotive.

It is a tiny olive drab Willys Jeep.

But it has no tires.

Instead of rubber, it is rolling on four custom cast steel train wheels. And it isn’t just going for a joy ride. This little four‑cylinder Detroit workhorse is pulling three fully loaded boxcars behind it, effortlessly hauling 10 tons of supplies through the jungle like it is *The Little Engine That Could*.

It looks absolutely ridiculous. It looks like a cartoon.

But in the Pacific Theater of World War II, this wasn’t a joke. This was the difference between life and death.

Welcome to one of the most ingenious, desperate, and brilliant field modifications in military history.

We all know the Jeep.

It is the icon of American freedom. General George Marshall called it “America’s greatest contribution to modern warfare.” We have seen footage of them bouncing over sand dunes in North Africa and speeding through liberated towns in France.

But the story nobody tells you—the story that gets lost in the history books—is about the time the United States Army turned their favorite car into a railroad empire.

To understand why on earth anyone would strip the tires off a perfectly good Jeep and put it on rails, you have to understand the nightmare of the Pacific.

In Europe, the Allies had roads. Sure, they were bombed out, but they were roads.

In the Pacific and the China–Burma–India Theater, there were no roads. There was only mud.

We aren’t talking about a few puddles. We are talking about the monsoon season.

When the rains came, the ground turned into a bottomless soup of chocolate pudding. It was a logistical catastrophe. The heavy 6×6 GMC trucks—the backbone of Army supply—were useless.

They would sink up to their axles the moment they left the hardstand. You could have a depot full of penicillin and bullets five miles away from the front line, but if you couldn’t move it, it might as well have been on the moon.

The Japanese Army knew this. They counted on the jungle to stop the American advance.

They figured that without roads, the heavy American war machine would suffocate.

But they forgot one thing.

They forgot about the American combat engineer.

These were guys who could fix a tank with a bobby pin and a stick of gum.

They looked at the muddy, impassable trails, and then they looked at the old narrow‑gauge colonial railway tracks that cut through the jungle. The trains were long gone, blown up or sabotaged, but the steel rails were still there, sitting on hard ballast, immune to the mud.

Then they looked at the Jeep.

It had the same wheel track width as the rails. It had a transmission with enough torque to pull a house down and, most importantly, it was sitting right there.

So in motor pools from the Philippines to India, the mechanics got to work.

They broke every rule in the manual.

They took the pride of the American auto industry and committed mechanical surgery.

They didn’t just want a car that could drive on tracks. They wanted a locomotive.

What follows is the story of how they did it. It is a story of field ingenuity, of welding torches sparking in the rain, and of a vehicle that was never designed to pull a train doing the impossible.

If it looks stupid but it works, it isn’t stupid.

And ladies and gentlemen, the railway Jeep worked like a charm.

Buckle up, because we are leaving the road behind.

Before we talk about the solution, you have to understand the nightmare.

You have to understand why a mechanic would look at a car and decide it needed to be a train—because you don’t cut up a perfectly good military vehicle for fun.

You do it because you are desperate.

You do it because the jungle is trying to kill you, and it is winning.

So, let’s talk about the enemy that didn’t carry a rifle.

Let’s talk about General Mud.

In the history books, we focus on the island‑hopping campaigns—*Iwo Jima*, *Okinawa*, the beaches. We think of sand.

But in places like Burma, New Guinea, and the Philippines, the war was fought in a green hell. And the geology of these places was unforgiving.

The soil there is a mix of volcanic ash and clay. When it is dry, it is dust.

But when the monsoon hits—and brother, does it hit—that dust turns into a sludge with the consistency of industrial glue.

Logistics officers call it impedance. The grunts just called it “the gumbo.”

Imagine you are a supply officer.

You have a convoy of the legendary “deuce and a half” trucks, the GMC CCKW. These are six‑wheel‑drive beasts, the trucks that supposedly won the war.

You load them up with crate after crate of K‑rations and .30 caliber ammunition. The drivers start the engines. They shift into low gear and roll out of the depot.

Ten minutes later, that entire convoy is stopped dead.

The trucks haven’t been shot at. They have simply sunk.

The mud in these regions is so deep and so soft that once the crust breaks, a truck sinks to its frame. The wheels spin helplessly, churning the mud into soup, digging the grave deeper.

You bring in a recovery vehicle to pull it out—and the recovery vehicle sinks too.

So the Army tried everything.

They tried using mules and horses, going old school. But the tropical diseases—surra and glanders—wiped the animals out faster than Japanese bullets.

They tried airdrops, but the canopy was so thick that half the parachutes got snagged in trees 100 feet off the ground.

The situation was becoming critical.

You had brave men on the front lines fighting for every inch of ground, bleeding and dying. And you had mountains of supplies sitting just 20 miles away that physically could not reach them.

It was a logistical heart attack. The arteries were clogged.

But there was one artery that was still open.

Cutting through the chaos were these narrow, rusted ribbons of steel.

The colonial powers—the British in Burma, the Americans in the Philippines—had built extensive narrow‑gauge railway networks years before the war.

They were designed to haul sugarcane, timber, and mining ore out of the deep bush. They ran on hard, ballasted beds that sat above the mud.

The rain didn’t wash them away. The mud didn’t swallow them.

It was the perfect highway.

There was just one massive problem.

There were no trains.

The retreating Japanese forces had been thorough.

They knew the value of those rail lines. They had taken the locomotives with them, or they had blown the boilers, or simply derailed them into ravines.

And even if you found a working steam engine, good luck finding the specific coal or cured wood needed to run it without clogging the firebox.

So picture the frustration.

You are an American engineer standing knee‑deep in sludge. You are watching a million dollars’ worth of trucks rusting in the mud.

And right next to you, mocking you, is a perfectly good, clear, solid steel railway track stretching all the way to the front line.

It is a highway with no cars.

You need a locomotive.

You don’t have time to ship one from the States. You don’t have the parts to build one from scratch.

You look around the motor pool. You see the massive, heavy trucks that are too wide for the narrow tracks. You see the tanks that would crush the rails.

And then your eyes land on the smallest vehicle in the lot: the Willys MB, the Jeep.

It’s light. It’s tough. It’s four‑wheel drive.

And you start to wonder: the wheelbase on that little guy looks awfully close to the width of those tracks.

Necessity is the mother of invention. But in war, desperation is the father.

The engineers realized they didn’t need a steam engine.

They had an internal combustion engine. They didn’t need a heavy iron horse.

They needed a pony. The idea was born.

But having the idea is one thing.

Making a rubber‑tired car run on steel rails without derailing and killing everyone on board—that is a whole different engineering challenge.

And that is where the real magic happened.

So the decision was made.

The Willys MB was going to trade its combat tires for iron shoes. But you don’t just drive a car onto a railroad track and hope for the best.

That is a quick way to derail and turn a supply run into a tragedy.

This required major surgery—and the operating room was a muddy tent in the middle of nowhere.

The first challenge was the shoes.

Rubber tires are great for gripping asphalt or dirt, but on a smooth steel rail, they are a liability.

If they get wet, they slip. If they get shredded by the jagged edges of the track, you are done.

So, the engineers had to source steel wheels.

In some units, they got lucky. They scavenged wheels from destroyed mine carts or old cane‑hauling wagons found rotting in the jungle.

But in other units, they had to make them from scratch.

Picture a field foundry: smoke billowing, sweat pouring as guys poured molten metal into makeshift molds to cast flanged wheels that would fit the Jeep’s lug pattern.

It wasn’t precision manufacturing. It was blacksmithing with a deadline.

Then came the issue of the gauge. This is where the math got tricky.

The standard railroad gauge in the U.S. is 4 feet 8½ inches. But the colonial railways in the Pacific were narrow gauge—usually 3 feet, or sometimes just a meter wide.

The Jeep, however, was built with a specific stance. If the tracks were narrower than the Jeep, the engineers had to get creative.

They fabricated custom steel discs—spacers that pushed the new steel wheels inward or outward to match the track width perfectly.

It was a precise alignment job done with crude tools.

If they were off by even half an inch, the Jeep would jump the tracks at speed.

But the biggest enemy of the railway Jeep wasn’t the width.

It was the physics of friction.

Here’s the thing about trains: they rely on weight. A locomotive can pull massive loads because it is incredibly heavy, which presses its steel wheels hard against the steel track, creating traction.

A Jeep? A Jeep is a featherweight. It only weighs about 2,400 pounds.

When they first tested these hybrids, they ran into a problem.

The engine would roar, the transmission would engage, and the steel wheels would just spin frantically on the rails like a blender on ice.

There wasn’t enough weight to grip the steel. The Jeep had the power, but it didn’t have the bite.

The solution? Good old‑fashioned dead weight.

The crews started loading the Jeeps up with everything they could find. They threw sandbags on the floorboards. They welded steel armor plating to the sides.

Sometimes the solution was just to pile as many guys as possible into the back seat.

They turned the Jeep into a heavy little brick.

With the added weight, the steel wheels bit into the track. And suddenly, that little four‑cylinder “Go‑Devil” engine could transfer its torque to the ground.

And then there was the steering. This was the strangest part for the drivers.

In a car, your life depends on the steering wheel. On the railway Jeep, the steering wheel was just a place to rest your hands.

The front axle had to be locked in place so the wheels wouldn’t turn left or right and derail the vehicle.

Imagine sitting in the driver’s seat, hurtling down a track at 30 miles an hour, approaching a sharp curve in the jungle.

Your instinct screams at you to turn the wheel, but you can’t. You just have to trust the rails.

You have to trust that the guy who welded your front axle knew what he was doing.

By the time the engineers were done, the vehicle looked like something out of a mad scientist’s garage.

It sat low and awkward. It rattled. It had weird overhangs and mismatched parts.

It was a mechanical Frankenstein.

But when they lined it up on the tracks and hooked up a string of flatbed cars loaded with ammunition, the engine didn’t whine.

It purred.

The surgery was a success.

The patient was no longer a car and not quite a train.

It was the railway Jeep, and it was ready to go to work.

When historians look back at World War II, they often get caught up in the grand strategies.

They talk about Eisenhower’s broad front or MacArthur’s island‑hopping campaign. They talk about the industrial might of Detroit turning out thousands of tanks.

But if you zoom in past the generals, past the factories, down to the sweat and dirt of the front line, you find the real story of how the war was won.

The railway Jeep is the perfect physical embodiment of a uniquely American philosophy of war.

It’s a philosophy that can be summed up in one gritty sentence:

If it’s stupid but it works, it’s not stupid.

Compare this for a second to the enemy.

The German military was famous for its precision engineering. They built tanks like the Tiger—complex, finely tuned, terrifying machines that were built like Swiss watches.

But Swiss watches don’t like mud. And they don’t like being fixed with a hammer.

When a German machine broke down in the field, it often needed a specialist and a factory part.

The American approach was different.

We built stuff that was loose, simple, and tough.

And we gave it to soldiers who had grown up fixing tractors on farms or hot‑rodding Fords in their garages.

We gave them a machine, but we also gave them the freedom to hack it.

The railway Jeep wasn’t in any official manual. There was no Pentagon blueprint for “Conversion, Kit, Rail, Willys MB.”

If a commander in Washington had seen the initial sketches, he probably would have laughed.

It looked dangerous. It looked unprofessional. It looked like a toy.

But out in the field, “professional” doesn’t mean looking good on parade.

Professional means getting the ammo to the guys who are being shot at.

This field ingenuity became a weapon all its own.

The railway Jeep proved that the most valuable tool in the U.S. arsenal wasn’t a gun. It was the cutting torch.

When the roads failed, they didn’t wait for orders. They didn’t wait for the weather to change.

They changed the vehicle.

And let’s talk about the legacy of this little iron pony. It did more than just haul cargo.

For the wounded, it was a godsend.

Have you ever ridden in the back of a 6×6 truck on a cratered dirt road? It’s violent.

For a man with a broken leg or a shrapnel wound, that ride is torture. It could kill you from shock alone.

But the railway Jeep—

It glided.

With those steel wheels on smooth steel rails, it was the smoothest ride in the jungle.

It became the most effective ambulance in the Burma Theater.

It saved lives simply by being gentle.

It also cemented the legacy of the Jeep itself.

Before the war, the Jeep was an unproven concept. By the end of the war, because of modifications like this, it was a legend.

We saw Jeeps with snorkels driving underwater. We saw Jeeps with stretched frames.

But the railway Jeep was the ultimate proof of the platform’s versatility.

It showed that this square, ugly little car was a blank canvas for the American soldier.

Decades later, looking back at the black‑and‑white photos of these Jeeps pulling boxcars, it’s easy to smile at how odd they look.

But make no mistake.

This wasn’t just a quirky experiment. It was a triumph of function over form.

It represents a time when the solution to a global crisis was found in a scrap pile by a couple of guys who refused to take “impossible” for an answer.

It reminds us that sometimes the best way forward isn’t to build a new road.

Sometimes the best way forward is to change your tires, lock your steering, and ride the rails.

This spirit—this refusal to be stopped by the mud—is what separated the victors from the vanquished.

The railway Jeep is long gone, its steel wheels likely melted down or rusted into the jungle floor.

But the lesson remains.

Adapt or die.

And nobody adapted quite like the American GI.

The war in the Pacific ended in 1945. The great armadas sailed home. The B‑29s were parked in boneyards. And the jungle, patient and relentless, began to take back what belonged to it.

Vines crept over the supply depots. Rain washed away the foxholes. Rust began to eat away at the steel rails that once served as the arteries of the Allied war machine.

Today, if you walk through those deep forests in Burma or the Philippines, you might stumble across a strange artifact half‑buried in the mud.

Maybe it’s a rusted piece of narrow‑gauge track. Maybe, if you are incredibly lucky, it’s a flanged steel wheel cast in a hurry by a desperate mechanic 80 years ago.

It is easy to look at the massive aircraft carriers or the atomic bomb and say, “That is what won the war.”

But history is often quieter than that.

History is found in the small things.

It is found in the squeak of a suspension spring and the hum of a four‑cylinder engine holding the line against disaster.

The railway Jeep didn’t drop a bomb. It didn’t sink a battleship. It didn’t liberate a concentration camp.

But in the darkest, wettest, most miserable corners of the earth, it did something perhaps even more important.

It kept the heart of the army beating.

It brought the morphine that eased a dying soldier’s pain.

It brought the letters from home that gave a weary Marine the strength to fight another day.

It brought the bullets that held the perimeter.

It serves as a permanent reminder that American victory wasn’t just about industrial output or overwhelming force.

It was about a state of mind.

It was about a refusal to accept the reality on the ground.

When the world said, “You can’t drive here,” the American soldier said, “Watch me.”

So, I want you to close your eyes one last time.

Imagine the sound of the rain hitting the broad leaves of a banana tree. The air is heavy and hot.

And in the distance, cutting through the silence of the jungle, you hear it.

Not the roar of a tank.

Not the scream of a fighter plane.

But the steady, rhythmic *clack clack clack clack clack* of steel wheels on steel rails.

Around the bend comes that little olive drab warrior. No tires, mud‑splattered, headlights taped over.

The driver exhausted but focused, gripping a steering wheel that doesn’t turn.

It passes you in a blur of motion, carrying the weight of the war on its small frame, disappearing into the green shadows of history.

It was the strangest train ever built.

It was a car that thought it was a locomotive.

And for a brief, shining moment in the middle of hell, it was the most beautiful thing on wheels.

The tires were gone, but the mission went on.

Thank you for watching.

If this story of mechanical grit inspired you, do me a favor—hit that subscribe button and share this video, because there are a thousand more stories like this buried in the mud of history, and I intend to dig up every single one of them.

Until next time, keep your powder dry and your wheels rolling.

News

The US Army’s Tanks Were Dying Without Fuel — So a Mechanic Built a Lifeline Truck

In the chaotic symphony of war, there is one sound that terrifies a tanker more than the whistle of an…

The US Army Couldn’t Detect the Mines — So a Mechanic Turned a Jeep into a Mine Finder

It didn’t start with a roar. It wasn’t the grinding screech of Tiger tank treads. And it wasn’t the terrifying…

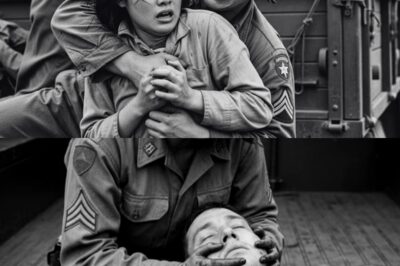

Japanese POW Woman WATCHED in Horror as Her American Guard Saved Her : “He Took a Bullet for Me!”

August 21st, 1945. A dirt track carved through the dense jungle of Luzon, Philippines. The war is over. The emperor…

Disabled German POWs Couldn’t Believe How Americans Treated Them

Fort Sam Houston, Texas. August 1943. The hospital train arrived at dawn, brakes screaming against steel, steam rising from the…

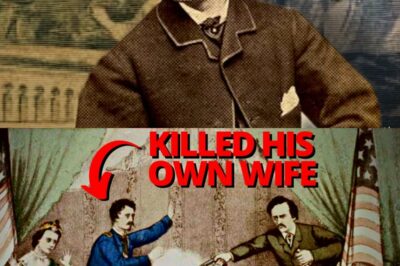

The Man Who Tried To Save Abraham Lincoln Killed His Own Wife

April 14th, 1865. The story begins with an invitation from President Abraham Lincoln and his wife Mary to attend a…

**“The Softest Secret of De Gaulle: The Disabled Daughter Who Changed a National Hero”**

Instead of hiding his daughter with Down syndrome, Charles de Gaulle raised her proudly, and she became the heart of…

End of content

No more pages to load